Definition of Retro Reflective Tape

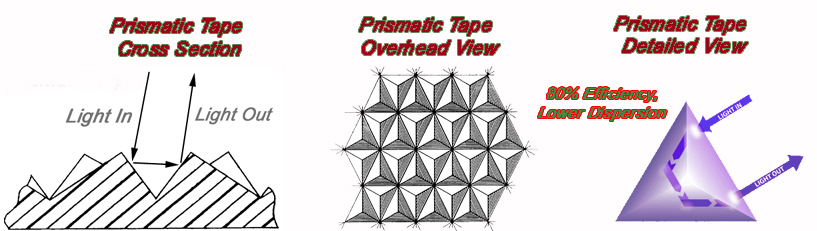

Definition of Retro Reflective Tape – (www.tapedealer.com) By definition, retro reflective tape is a film that either through the use of glass spheres or man made prisms, reflects light or radiation back to its source. (Source – Cambridge English Dictionary) This seems like a simple task but in fact it is quite complicated. Just like …