History of Reflective Paint – (www.tapedealer.com)

Who actually invented reflective paint? The following outlines the invention and advancement of ready mixed Retro Reflective Coatings (also known as Reflective Paints) from their inception until now. Ready mixed simply means that the reflective glass spheres are already in the paint mix, making the application a one step process. This is in contrast to the method of applying glass beads over wet paint which is known as the drop on method.

Paint is a substance which is spread over a substrate that when dry, leaves a thin coating. A reflective coating or paint is different in that at night it returns or bounces light back to the source, much like reflective tape does. Bouncing back the light to a viewer who is within the cone of reflectivity makes the paint appear bright white. This bright light contrasts itself from the surrounding surfaces and provides the contrast needed for high visibility. (Example – a street sign illuminated by headlights)

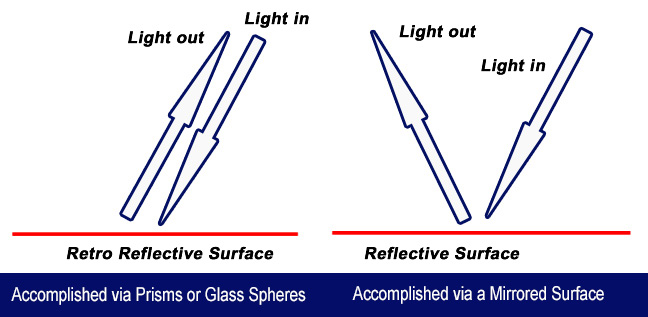

(Reflective means to bounce light back in any one direction. Retro reflective means to send light back to its source. Mirrors are reflective and reflective paint or reflective tape are retro reflective.)

History of Reflective Paint.

There are two primary components that make up all reflective paints. A liquid binder or paint (usually clear) and reflective glass beads. There are often various other components used in the formula, however, these are the main ingredients. Paint itself was invented thousands and thousands of years ago by early civilizations, however, it wasn’t until the early 1900’s that perfectly round glass beads that would reflect light were invented. And since you need both paint and glass beads for reflective paint, no one could have created it prior to the discovery of reflective glass spheres.

In 1914, Rudolph Potters, along with his brother Paul, developed a method for manufacturing perfectly round glass beads. Spheres that would reflect light back to the source of the light.

Note – retro reflectivity exists in nature in the form of rain drops and the eyes certain animals. The cats eye is probably the best example. A glass sphere reproduces this phenomenon.

It was discovered that by dropping hot molten glass, it would form an almost perfect sphere as it fell. So Potters developed a controlled way to produce perfectly round beads in large quantities. The method for creating glass spheres, and the apparatus or machinery needed for the process are what he later patented. The creation of glass spheres that were almost perfectly round was a very important discovery and single handedly revolutionized the traffic safety industry. From the creation of reflective glass beads came brighter more vivid movies screens, retro reflective highway lines, reflective sheeting, reflective garment trim, and more. In 1941, Potters Beads patented the invention titled the “Method and Apparatus for Producing Glass Beads“. Once Potters Beads began mass production of their glass beads, a variety of other inventions and patents that utilized their the micro reflective glass spheres quickly followed.

The reflective movie screen was one of the first applications that used the micro glass beads mixed with a binder. The term silver screen became popular because in the 1910’s, movie screens began to be coated with a reflective paint that gave them a silvery appearance. These coated screens reflected more light back towards the audience, giving them a better and brighter picture. The beads used for these screens were of course Potters Beads. So to be accurate, the first real mention of reflective coatings or paint being used in commerce would have been for movie screens. At that time, the actual reflective paint used to coat the screens was invented, but not patented. An official patent of a retro reflective paint would take place years later. And it would be for an entirely different purpose.

Overwhelmingly, the largest application for reflective glass beads is in the highway safety industry. Automobiles have lights, and at night they have to be able to navigate safely. To this day, reflective glass beads are used all over the world in large quantities as a way to make painted road stripes and thermoplastic road stripes visible at night. And because reflective street lines wear away, the demand for new beads is never ending.

Note – The standard way to create a reflective stripe on a highway or road, crews put down a layer of paint or hot thermoplastic, apply glass beads to the surfaces and let the painted line dry, or the thermoplastic line cool. The result is a reflective stripe that lights up when car lights hit it.

In the late 1930’s and 40’s, a company called 3m became very interested in retro reflective traffic products. Many people know that 3m invented what we now know as reflective tape or sheeting for traffic signs, however, what most do not know is that reflective tape was invented out of an effort to create reflective pavement stripes. They experimented with an adhesive film with glass beads on top that could be adhered to pavement The idea worked, however, longevity was a problem so the idea for using this invention for road stripes was put on hold. The experiment led to the invention of retro reflective sheeting in 1941, an invention that literally changed the world of night time driving. But 3m was not at all done with trying to invent a reflective road striping product.

Note – later, 3m would continue their pavement tape line and create what we now know as Stamark pavement striping products. Long lasting, simple to apply, and reflective.

As stated before, until the late 40’s, the only way to make road stripes reflective was by first applying a layer of paint, and then going over the wet paint with glass beads. This two step process is referred to as the drop on method and the glass beads used are called drop on highway beads. This method of application was used in the very beginning and is actually still the way it’s done today for large striping projects. However, in the 40’s and later, the goal of inventors was to take the two steps of the drop on method and combine them into one simpler step. This seems fairly simple, however, as with any process or invention, there were problems to overcome.

Note – the problem that engineers were trying to overcome was the tendency of glass spheres to settle in a paint solution and submerge below the surface. This was an issue, because to reflect, glass beads need to be exposed on top of the painted surface so that light can enter and be returned.

In 1949, the 3m company developed a paint that mixed reflective glass spheres in with paint. The product was designed to be sprayed onto a road surface and when dry, it would produce a reflective stripe. The invention was labeled “Highway Marking Paint Containing Glass Beads“. Since glass beads were all through the layer of paint, as the lines wore, new glass beads would be exposed so that reflectivity was maintained over time. The invention worked, however, it did not replace the drop on method. This patent expired in 1968.

In 1956, American Marietta invented a new reflective paint. This creation was called “Centerline Paint“. This paint would use what is called Specular or Mirror reflectivity instead of Retro Reflective Glass Beads. Reflective crushed glass was mixed with paint to create little mirrors in the surface that would reflect light back to car headlights. This mix of crushed glass also created a non-skid surface, whereas glass beads tended to be slippery when wet. This patent expired in 1975.

In 1958, American Marietta modified their reflective road paint to include larger glass spheres. This added brightness while maintaining the non-skid characteristics of the line. This patent is described as “Road Marking Paint“. The patent expired in 1978.

In 1966, the 3m company came up with yet another reflective paint that they called “Reflective Coating Compositions Containing Glass Beads, Metal Flake Pigment and Binder“. This was probably the most creative iteration of this product in that it added ingredients to both increase reflectivity, and add color to the coating. This was accomplished through the use of colored metal flakes that were smaller in size than the glass spheres. When applied to a surface, and while the paint was still in a liquid form, the flakes would settle below the micro beads and provide a colored reflective background. In this iteration, higher index beads were used for enhanced brightness. This invention was also different from previous ones in that it was intended to be used by sign makers who wanted an easy one step way to create a reflective sign background. For example, if a bill board needed to be seen at night, parts of that sign could be made reflective so that oncoming traffic would see it. The patent for this product expired in 1983.

In 1977, 3m filed for a patent referred to as a “Retro-Reflective Liquid Coating Composition“. The patent was granted in 1982. The invention was unique in that it was a thick gel type coating. The gel consistency kept the beads in suspension, and the solvents in the coating caused the mixture to dry quickly. When it dried, the coating formed little domes or mounds on a surface that were instantly retro reflective. These raised retro reflective domes provided reflectivity at more angles than a standard flat surface. The stated purpose of the invention is as follows – A coating composition useful, inter alia, to form mound-shaped retroreflective marks that rapidly actuate photo scanner sensing devices. The patent for this invention expired in 1999.

To the best of my knowledge, there are currently no active patents for reflective paints or coatings, and since every conceivable way of creating it using glass spheres has been exhausted, new patents are highly unlikely. In other words, all patents on reflective paint appear to have run out, and this product is now part of the public domain.

With that being said, there are many reflective paints and coatings sold today. Some are spray on paints, some are brush (or roller) applied, and others are in the form of inks that are applied by the screening printing process. Some common uses for reflective coatings are as follows –

- Reflective Arts and Crafts

- Bicycle Frames and Helmets

- Offshore Crab & Lobster Floats

- National Parks – Marking Non Uniform Objects

- Screen Printing Shirts, Shoes and Hard Surfaces

- Parking Lot Legends and Logos

- Trail Marking for Hunters

In summary, although attempts to replace the drop on reflective road striping method did not pan out as expected, reflective coatings are very much a part of modern day personal safety, just in different applications.

For more information about reflective paints and tapes, go to www.reflective-paints.com. And as always, if you have any questions, feel free to contact us using the contact link to the left.