Red / White DOT C2 Reflective Truck Tape Specifications – (www.tapedealer.com)

DOT Truck (Tractor Trailer) marking requirements were set up by the FMCSA to help improve visibility in low light conditions and reduce the probability of fatal motor vehicle crashes into the sides or back of stopped or parked trucks and tractor trailers at night or in poor visibility conditions.

DOT Truck (Tractor Trailer) marking requirements were set up by the FMCSA to help improve visibility in low light conditions and reduce the probability of fatal motor vehicle crashes into the sides or back of stopped or parked trucks and tractor trailers at night or in poor visibility conditions.

On December 10, 1992, the National Highway Traffic Safety Administration or NHTSA published a final ruling that required trailers manufactured on or after December 1, 1993 having an overall width of 80 inches or more and a gross vehicle weight rating (GVWR) of more than 10,000 pounds, be equipped on the sides and rear with a means for making them more visible on the road. The NHTSA ruling allows trailer manufacturers to install either red and white retro reflective tape or sheeting or reflex reflectors. This tape is commonly referred to as DOT C2 reflective tape and is thus marked for easy identification (Exemption – pole trailers and trailers designed exclusively for living or office use)

While the term “DOT C2” reflective tape is used quite often in regards to marking tractor trailer rigs 80 inches wide or wider and over 10,000 lbs GVWR, what the term “DOT C2” means is seldom discussed. Most people know that the letters DOT mean “Department of Transportation. Also, some people know that the term C2, C3 or C4 refers to the width of the tape. (2″,3″ or 4”) Most people do not know what it takes for a reflective tape to be certified as “DOT C2, C3, or C4”. This article is meant to help you understand what these requirements are so that you can be sure that you are using the correct product on your vehicle. In the event of an accident, having the proper markings is especially important. We recommend Oralite (formerly Reflexite) DOT tapes. They invented prismatic reflective tape and their products are respected and recognized around the world. The downsides to using a cheap substitute are simply not worth it.

In order to be certified as DOT C2, C3 or C4 tape, certain requirements have to be met. These requirements involve the construction of the tape, the color, the width, the spacing of the alternating colors, the performance, and the reflectivity. If a tape has been certified to meet these standards then the manufacturer is allowed to put DOT C2 certification on it. The specifics of the requirements are as follows. (Source – Federal Motor Carrier Safety Administration 393.11)

Construction – The requirements for the basic construction of the film are very straight forward. This is how virtually all reflective tapes are constructed. The regulation is as follows:

S5.7.1.1 Construction. Retroreflective sheeting shall consist of a smooth, flat, transparent exterior film with retroreflective elements embedded or suspended beneath the film so as to form a non-exposed retroreflective optical system.

Color – DOT tape must be made with white and red alternating colors. The white color on prismatic tapes often looks silver but reflects white at night. The exact wording of the regulation is as follows:

(a) Retro-reflective sheeting shall be applied in a pattern of alternating white and red color segments to the sides and rear of each trailer, and to the rear of each truck tractor, and in white to the upper rear corners of each trailer and truck tractor, in the locations specified in S5.7.1.4, and Figures 30–1 through 30–4, or Figure 31, as appropriate. (see this article for placement details)

Spacing -The red and white (silver) segments are required to be a minimum of 12 inches plus or minus 6 inches. That would be between 6″ and 18″ There is an exception where the tape must be trimmed to avoid obstructions when installed. Also, neither the red or white colors can exceed two thirds (2/3) of the total.

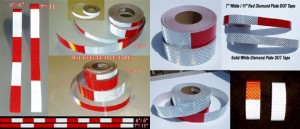

There are two types of DOT tape available. A 7″ white / 11″ red and a 6″ white / 6″ red. If you run the numbers you will see that both meet the spacing requirement. On 7/11 tape the 7″ white would represent 39% of the aggregate and the 11″ red would represent 61%. The 6/6 would be 50% each. To the best of my knowledge all 50 states allow you to use either the 7/11 or 6/6 type DOT tape. The regulation is quoted below:

(b) Except for a segment that is trimmed to clear obstructions, or lengthened to provide red sheeting near red lamps, each white or red segment shall have a length of 300 mm ±150 mm.

(c) Neither white nor red sheeting shall represent more than two thirds of the aggregate of any continuous strip marking the width of a trailer, or any continuous or broken strip marking its length.

Width – DOT certified tape can be 2″ wide, 3″ wide or 4″ wide. The most popular and cost efficient size is 2 inches but for larger trucks many users prefer the 3 and 4 inch widths in either the 6/6 or 7/11. The more visible the truck the better. Also, in the event of an accident it is important to be able to show due diligence when it comes to vehicle conspicuity. The specific regulation is as follows:

(d) Retroreflective sheeting shall have a width of not less than 50 mm (Grade DOT-C2), 75 mm (Grade DOT-C3), or 100 mm (Grade DOT-C4).

Reflectivity & Performance – This is one of the most important aspects of this tape. A bright tape can be seen from longer distances. For highway applications this is very important. To meet the DOT C2,3,4 requirements a tape must meet all the requirements for ASTM D4956-90 Type V Sheeting EXCEPT for the reflectivity. These requirements would include things like adhesion, colorfastness, flexibility, shrinkage, weathering, etc… Reflectivity requirements are basically equal to Type III or High Intensity Glass Bead tape. To be safe, a Prismatic DOT tape is recommended. This will assure that the reflectivity far exceeds the minimum requirements. The exact wording of the regulation and a reflectivity chart are included below:

S5.7.1.2 Performance requirements. Retroreflective sheeting shall meet the requirements of ASTM D 4956–90, Standard Specification for Retroreflective Sheeting for Traffic Control, for Type V Sheeting, except for the photometric requirements, and shall meet the minimum photometric performance requirements specified in Figure 29.

(e) The coefficients for retroreflection of each segment of red or white sheeting shall be not less than the minimum values specified in Figure 29 of this standard for grades DOT-C2, DOT-C3, and DOT-C4.

Figure 29—Minimum Photometric Performance of Retroflective Sheeting in Candela/Lux/Square Meter

| Entrance angle | Observation angle | Grade | |||

|---|---|---|---|---|---|

| 0.2 Degree | 0.5 Degree | ||||

| White | Red | White | Red | ||

| -4 degree | 250 | 60 | 65 | 15 | DOT–C2 |

| 30 degree | 250 | 60 | 65 | 15 | DOT–C2 |

| 45 degree | 60 | 15 | 15 | 4 | DOT–C2 |

| -4 degree | 165 | 40 | 43 | 10 | DOT–C3 |

| 30 degree | 165 | 40 | 43 | 10 | DOT–C3 |

| 45 degree | 40 | 10 | 10 | 3 | DOT–C3 |

| -4 degree | 125 | 30 | 33 | 8 | DOT–C4 |

| 30 degree | 125 | 30 | 33 | 8 | DOT–C4 |

| 45 degree | 30 | 8 | 8 | 2 | DOT–C4 |

DOT Certification Logo – The DOT-C2 designation is to appear on the tape at least every 12 inches. The characters should be at least 3 mm tall and stamped in indelible ink or an equivalent. The exact wording is below:

S5.7.1.5 Certification. The letters DOT-C2, DOT-C3, or DOT-C4, as appropriate, constituting a certification that the retroreflective sheeting conforms to the requirements of S5.7.1.2, shall appear at least once on the exposed surface of each white or red segment of retroreflective sheeting, and at least once every 300 mm on retroreflective sheeting that is white only. The characters shall be not less than 3 mm high, and shall be permanently stamped, etched, molded, or printed in indelible ink.