MUTCD Reflectivity Standards – (www.tapedealer.com)

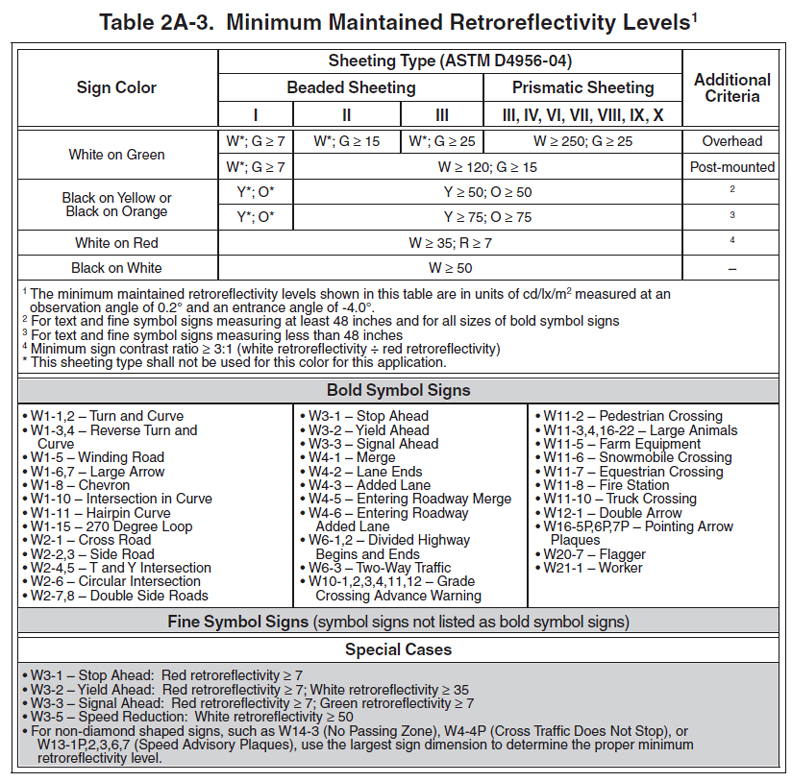

The chart below shows the minimum requirements for retro reflective sheeting and tape for signs and applications that are under the jurisdiction of the Federal Highway Administration (FHWA) and the Manual of Uniform Traffic Control Devices (MUTCD). The chart can also be used as a guideline for exempt applications. The deadlines for compliance are as follows:

- Assess the signs on their roads and develop a replacement plan within four years of the final ruling. (January 22, 2012)

- Replace non-compliant warning and regulatory signs within seven years of the final ruling. (January 22, 2015)

- Replace guidance and street name signs within ten years of the final ruling. (January 22, 2018)

The summary after the chart will explain what the chart means for different types of signs.

On the left hand side of the chart you will find the colors used for different signs. At the top you find the type of reflective tape required and to the right are the overhead and ground mounted categories (additional criteria). To use the chart first determine whether your sign is an overhead or a ground mounted sign. Most are ground mounted. Then determine the colors that will be used on the left. Then go to the right until you find the sheeting that meets the minimum. As you can see, for yellow and orange background signs a type 2 sheeting is required. For red and white background signs a type 1 is all that is needed. Also, when the chart says black it means a “non reflective” black. When there is an asterisk * after a color/type that means it cannot be used for that type of sign.

When a color/type has a > and then a number next to it that means that the sheeting must exceed the number in reflectivity measured in cd/lx/m2. (candelas) Many people call this the candlepower of the sheeting or tape. To see charts on the reflectivity of the different types of reflective sheeting click here.

The minimum contrast ratio is also important. This simply means that the candlepower or reflectivity of one color must exceed the other by a certain factor. For example, the white stop on a stop sign must be 3 times brighter than the red. If you used the same type of material for both color this contrast is usually achieved automatically. If you used a prismatic red background and an engineer grade white then you may have some problems with this ratio.

Basically, for ground mounted signs (on a pole), you are always safe using a type 2 material or better. For black on white or white on red signs (speed limit or stop sign) a type 1 engineer grade film is acceptable. (white engineer grade is about 75 candlepower) For overhead signs like what you would see over an interstate you are required to use a type 3 or better prismatic sheeting.

As you can see, since ground/pole mounted signs make up the bulk of all signs, type 1 and 2 sheeting are the most needed. This is not expected to change for quite a while. The type 1 and 2 films are very affordable. The prismatic films are much more expensive. Since prismatic films are only required on overhead signs the new regulations do not have to substantially increase your sign budget. The main thrust of the new law is to require cities, counties and states to have a plan for maintaining signs to the minimum level of reflectivity.

The following is a quote from the MUTCD manual showing the options for managing sign reflectivity.

Section 2A.08 Maintaining Minimum Retroreflectivity

Support:

01 Retroreflectivity is one of several factors associated with maintaining nighttime sign visibility (see Section 2A.22).

Standard:

02 Public agencies or officials having jurisdiction shall use an assessment or management method that is designed to maintain sign retroreflectivity at or above the minimum levels in Table 2A-3.

Support:

03 Compliance with the Standard in Paragraph 2 is achieved by having a method in place and using the method to maintain the minimum levels established in Table 2A-3. Provided that an assessment or management method is being used, an agency or official having jurisdiction would be in compliance with the Standard in Paragraph 2 even if there are some individual signs that do not meet the minimum retroreflectivity levels at a particular point in time.

Guidance:

04 Except for those signs specifically identified in Paragraph 6, one or more of the following assessment or management methods should be used to maintain sign retroreflectivity:

A. Visual Nighttime Inspection—The retroreflectivity of an existing sign is assessed by a trained sign inspector conducting a visual inspection from a moving vehicle during nighttime conditions. Signs that are visually identified by the inspector to have retroreflectivity below the minimum levels should be replaced.

B. Measured Sign Retroreflectivity—Sign retroreflectivity is measured using a retroreflectometer. Signs with retroreflectivity below the minimum levels should be replaced.

C. Expected Sign Life—When signs are installed, the installation date is labeled or recorded so that the age of a sign is known. The age of the sign is compared to the expected sign life. The expected sign life is based on the experience of sign retroreflectivity degradation in a geographic area compared to the minimum levels. Signs older than the expected life should be replaced.

D. Blanket Replacement—All signs in an area/corridor, or of a given type, should be replaced at specifiedintervals. This eliminates the need to assess retroreflectivity or track the life of individual signs. The replacement interval is based on the expected sign life, compared to the minimum levels, for the shortest-life material used on the affected signs.