How Glass Bead and Micro-Prismatic Reflective Tapes Are Made – www.tapedealer.com

Reflective tape is made using machines that bond together multiple layers of material into one film. There are two main types of reflective tape, glass bead and micro-prismatic. They reflect in two different ways but are made in similar fashion with glass bead tape being the less complicated of the two to produce.

Engineer Grade Glass Bead Reflective Tape

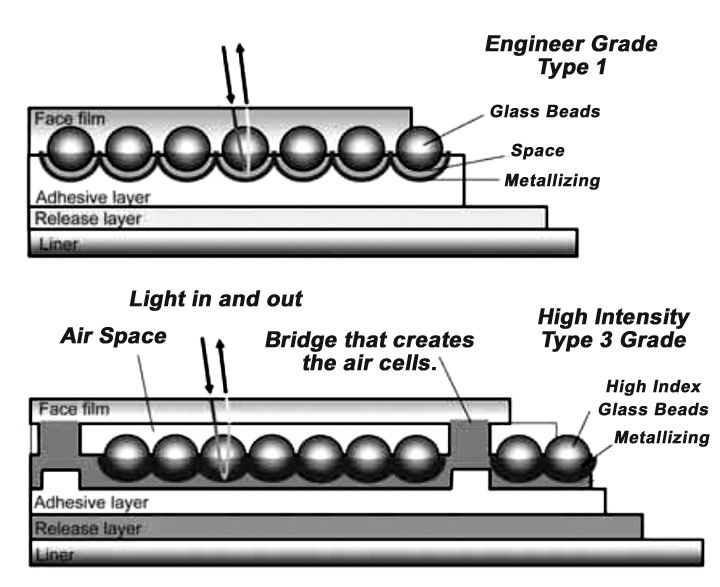

Engineer grade reflective starts with a carrier film that is metalized on the top. Glass beads are applied to this layer so that about 50 percent of the bead is embedded in the metalized layer. This gives the beads their reflective properties. Then a layer of either acrylic or polyester is applied over the top. This layer can be clear to made white reflective tape or it can be colored to create the different color reflective tapes. A layer of adhesive is then applied to the bottom of the tape and a release liner is applied to that layer. It is rolled up, slit to width and then sold. Note – an acrylic layered film will not stretch and a polyester layered film will. Because of the heat used in the manufacturing process engineer grade films end up being a single layer so they will not delaminate.

High Intensity Glass Bead Reflective Tape

High intensity type 3 reflective tape is made in layers also. The first layer if one that has a grid built into it. Normally a honeycomb type pattern. This pattern is what will hold the glass beads so that they are in separate cells. The glass beads are bonded to the bottom of this cell then a layer of acrylic or polyester is applied over the top of the cell so that there is a small air space above the beads. (high index beads) This layer can be clear or a color. Then a layer of adhesive and a release liner are applied to the bottom of the tape. Note – an acrylic layered film will not stretch and a polyester layered film will. Although the layers in high intensity are bonded together, they can delaminate.

Metalized Micro-Prismatic Reflective Tape

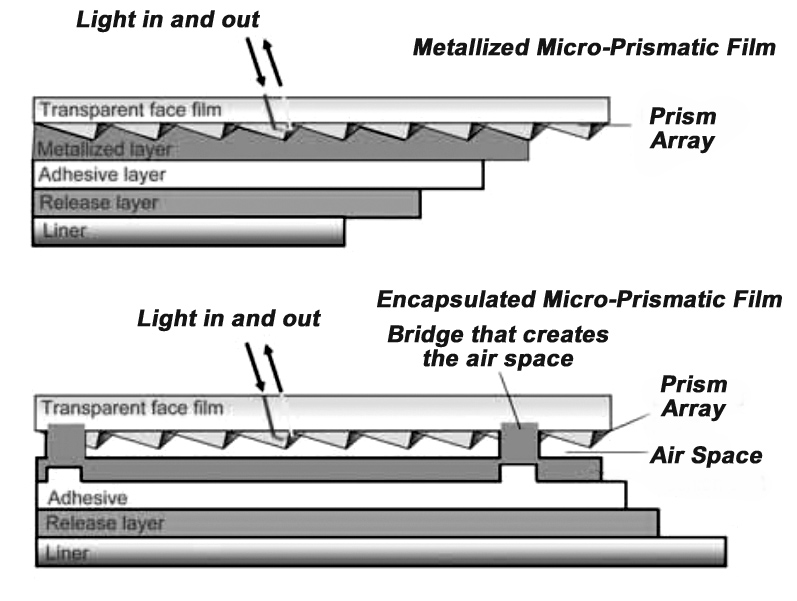

Metalized micro-prismatic reflective tape is made by first creating a prism array out of clear or colored acrylic or polyester (vinyl). This is the top layer. This layer provides reflectivity and returns light back to the source. A colored layer would return light back to the source but in a different color. This layer is metalized to enhance its reflectivity. Then a layer of adhesive is applied to the back and a release liner is applied. Because of the heat used in this process the layers of metalized prismatic will not delaminate. This is especially beneficial in applications such as vehicle graphics or any other application where the tape may be treated harshly. Reflexite invented prismatic reflective tape and their tapes do not delaminate.

Non Metalized Micro-Prismatic Reflective Tape

Much like metalized films, the first step in creating non metalized reflective films is to create the prism array out of acrylic or another clear resin. This will be the top layer of the film. It can be clear or colored. In order to create a whiter or a more vivid colored film, the prism layer is adhered to a grid that forms a sort of honeycomb pattern. This creates an air layer below the prisms. The surface below the air layer is white. The prism layer and the grid layer are bonded together but can come apart meaning that non metalized films can delaminate. By eliminating the metalizing of the prisms the tapes are more vivid since the color does not have to compete with the silver metalizing layer. Non metalized films are more vivid but not necessarily more reflective.

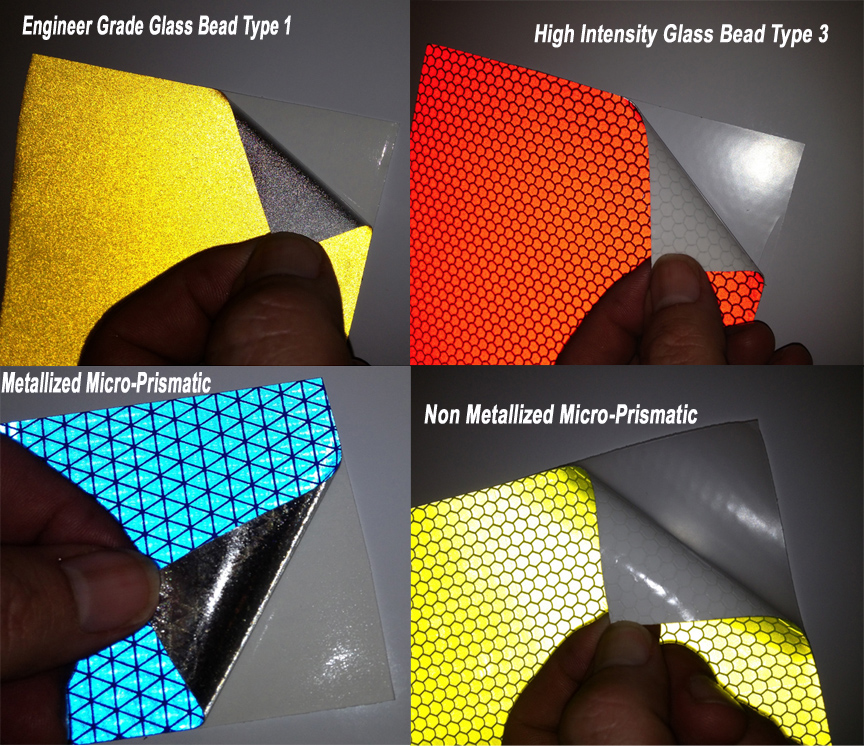

The image below shows the 4 types of reflective films. All are made in a similar way. The glass bead engineer grade film is the easiest to make and thus the least expensive. The high intensity is the next easiest and next in price. The metalized micro-prismatic films are the most expensive to make but are the brightest and toughest of all the reflective tapes. They are perfect for dynamic or harsh environments. The non metalized films are less expensive to make than metalized films. Non metalized films have the advantage of being more vivid in the daytime and are popular for sign sheeting and other static applications.