Enclosed Lens versus Encapsulated Lens – Retro Reflective Sheeting (enclosed=engineer grade / encapsulated=high intensity)

Reflective Sheeting comes in several types, colors, brightnesses, etc.. Some of the terminology that describes the different types of reflective sheeting can be confusing. This article is going to define the terms enclosed lens and encapsulated lens reflective sheeting. These terms have to do with the construction of the reflective film. These 2 methods of construction also define the look and feel of the tape. In other words you can look at a reflective tape sample and tell which type of construction was used. (In a separate article I will be discussing metallized and non metallized prismatic sheeting.)

Enclosed Lens Retro Reflective Sheeting

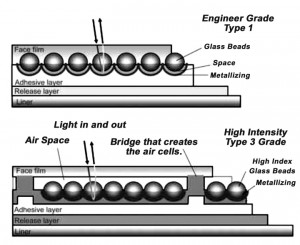

This method of construction applies only to glass bead type reflective films. Enclosed lens is also known as engineer grade (type 1) or super engineer grade (type 2) reflective sheeting. The glass beads provide the reflectivity by bouncing light back to the source. Each glass bead is like a lens. In an enclosed lens film the glass beads are completely surrounded by the flexible polymer that makes up the film. Nothing is able to get to the beads except light. The polymer that surrounds the beads is often tinted which is what creates the different colors. The top part of the image below shows how this works. With this type film you can cut it anywhere you wish and not affect the integrity of the beads. This is why this type film is often used for graphics applications such as letters and numbers on vehicles. Enclosed lens films generally have no visible pattern. Just a smooth color like white, red, green, blue, black, yellow, brown, gold or orange.

Encapsulated Lens Retro Reflective Sheeting

Encapsulated lens reflective sheeting also refers to glass bead type films. Specifically a type 3 high intensity film. In this type of construction the glass beads are encapsulated in cells. As long as the cell is intact, water and the elements cannot get to the actual bead. However, when the film is cut the cells on the edge are exposed and water intrusion can occur if the cell is not sealed using a clear coat. (only the cells on the edge would be affected) In other words, the beads are only protected within the cell. Because the beads are not completely surrounded by a polymer, they reflect more brightly. The top of the cell they are in is either clear or tinted to create a colored film. The bottom of the image above shows this type of construction. If you look at an encapsulated film you will be able to see the cells as either a honeycomb pattern or diamond pattern. If you look very close you will see the small beads. (If you see prisms within the cell then you are looking at a non metallized prismatic film which we will discuss in a different article.)